- Home

- > Operational Benefits

- > Material Management

Material Management

2 simple survey tasks

- No more

supply delay risks - No more

repetitive receipt quantity verification - No more

excessive, inefficient travel to the storage warehouse - No more

breaking down of mixed pallet loads - No more

intricate parts cluttering on the production line - No more

shipment staging - No more

delays due to engineering change management

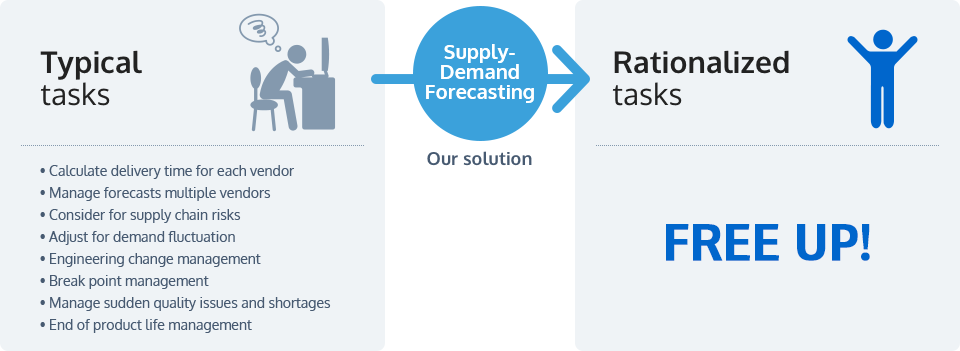

Supply-Demand Forecasting

Supply-Demand Forecasting

Simply provide your forecast requirements and eliminate your supply chain worries

Building on our proactive supply chain communication tools, we could instantly adjust supply timing across a vast number of vendors and drive down supply chain risks. You could get instant information on where your parts are, and when they will be replenished.

Learn more about our IT Platform

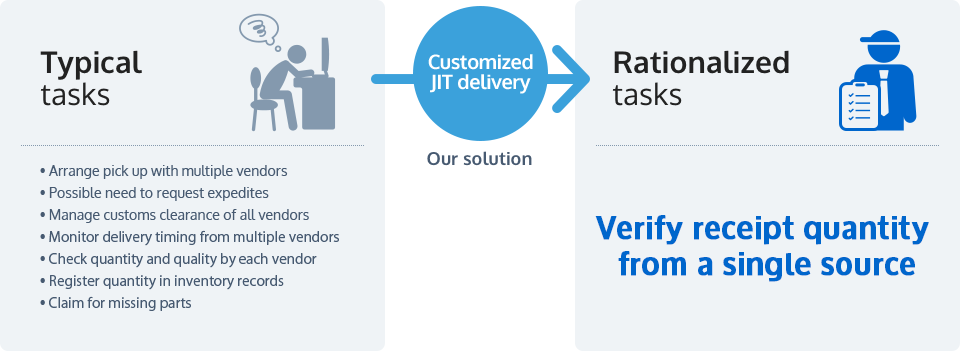

Customized JIT delivery

Customized JIT delivery

Parts are ready when needed

We ensure that just the right amount of fastening components and automotive parts are delivered at the required time.

We also take pride in our consistent track record of bringing that high quality solution to all customers across the automotive supply chain.

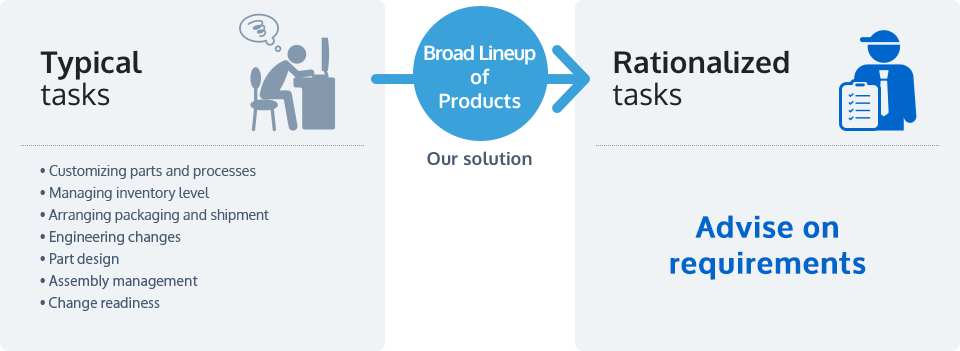

Broad Lineup of Products

Broad Lineup of Products

Focus on your highest priority requirements

Based on your priorities, we can leverage our broad range of product and relevant expertise to provide worry free support for your assembly line allowing you to concentrate on your critical responsibilities.

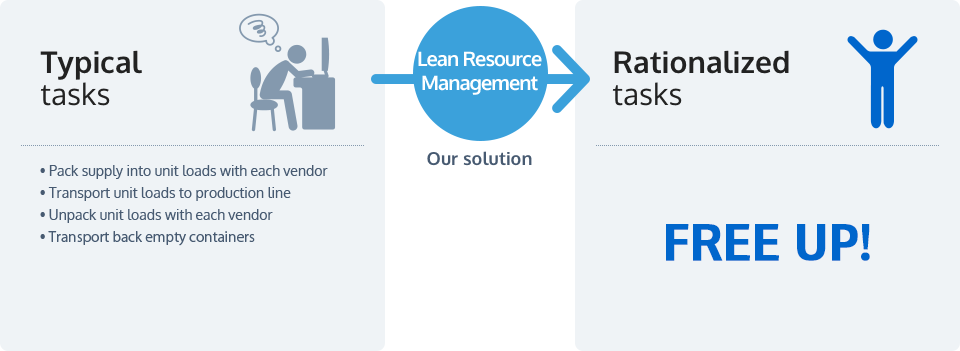

Lean Resource Management

Lean Resource Management

Reduce your fastener related material handling requirements

We can reduce tedious task inherent to managing inventories while bolstering the efficiency of your production line through our lean resource management scheme.